Creation to restructure the oilseed sector

1983−2002

1983

Creation of Saipol

Creation of Saipol by Sofiprotéol (which became Avril in 2015) on 9 November 1983 to take over and structure the French oilseed processing industry, which was in difficulty at the time following the bankruptcy of the CNTA (Comptoir National Technique Agricole – National Syndicate of Agricultural Techniques). Saipol, with the support of Sofiprotéol, reorganised the original industrial park, and then continued to grow by investing in the factories maintained in the territory.

1990

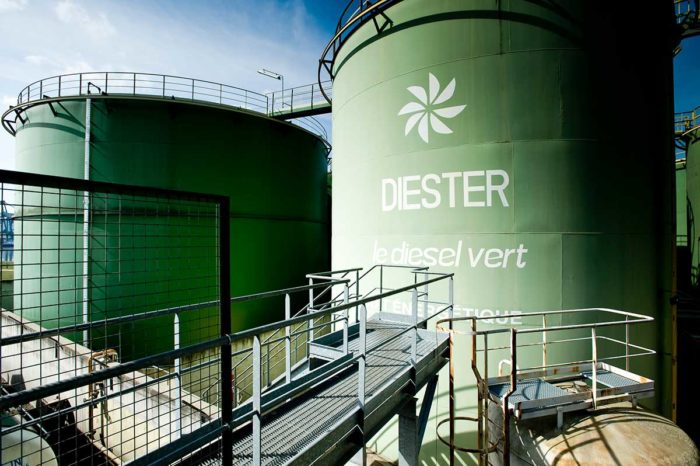

Creation of Diester®

In Compiègne, the first pilot plant for the production of biodiesel from the transesterification of rapeseed oil is built. The Diester® brand is created for the biodiesel produced by the Group. Saipol produces Diester® and sales are made by Diester Industrie, a new company created in 1992. Diester Industrie and Saipol merge and keep the name Saipol in 2014.

1992

Start-up of the Rouen plant

Start-up of a rapeseed crushing and vegetable oil refining unit in Grand-Couronne (76), near Rouen.

1995

Start-up of the world’s first biodiesel production unit

Start-up of the world’s first industrial-scale biodiesel production unit (120,000 tonnes) at the Saipol site in Grand-Couronne.

Downstream development and growth

2003−2012

2003

Development towards the packaging of vegetable oils

After becoming the leading producer of French refined oils, Sofiprotéol acquired Lesieur and consolidated an activity from seed to finished product. As of 2004, the Group has produced the Fleur de Colza oil: an oil rich in omega 3 produced by Saipol, packaged and marketed by Lesieur. 10 years later, in 2013, Lesieur was reintegrated into the holding company of the Sofiprotéol group and is now a subsidiary of the Avril Végétal division.

Learn more about Lesieur

2004

Saipol responds to the French biofuel plan

From 2004 to 2008, Saipol responded to the French biofuel plan which, at the time, aimed at incorporating 7% biodiesel into diesel fuel distributed. A large investment plan resulted in an increase in oilseed crushing capacity and in building biodiesel production units in Grand-Couronne, Bassens, Sète, Montoir-de-Bretagne, Cappelle-la-Grande and Le Mériot.

2008

A new Saipol plant in Meriot

Built between November 2005 and December 2007, since 2008 the Saipol plant in Mériot has been producing vegetable oils, rapeseed cake, Diester biodiesel and vegetable glycerine from rapeseed grown within a 150 km radius of the plant.

The plant was officially inaugurated on 5 February 2009 by Luc Chatel, Secretary of State for Industry and Consumer Affairs and Government Spokesman.

2010

Saipol acquires Expur

Saipol acquired Expur, a Romanian crusher established in the oilseed production basin of Eastern Europe and the Black Sea. Expur processes rapeseed and sunflower seeds for the production and packaging of vegetable oils for food, meal for animal feed, biodiesel and crude vegetable glycerine.

Read more about Expur

Consolidation of industrial activities

2013-2015

2013-2014

Restructuring of Saipol and Diester Industrie

The revision of the European objectives regarding blending of biofuels has led Saipol and Diester Industrie to reduce their industrial footprint and refocus production on 6 industrial sites. The Venette (crushing and esterification) and Cappelle-La-Grande (esterification) sites were closed.

In June 2014, Saipol was restructured through a merger-absorption arrangement by Diester Industrie, and following this transaction adopted the name “SAIPOL”.

2014

Improving energy performance

Saipol continues to invest in improving the energy performance of its industrial facilities and promoting biomass as an energy source for steam production at its industrial sites: biomass cogeneration at Grand-Couronne, sunflower hulling and biomass boiler at Bassens, biomass boiler at Sète, biomass boiler at Lezoux.

A new strategy for Saipol

2015-2020

2015 - 2017

New governance and strategy

From 2017 onwards, Saipol, faced with international competition in the commodity biodiesel market, has initiated its growth strategy in speciality products.

Saipol launches Transform, its transformation programme which aims to deploy its future growth drivers within the Avril plant sector by 2023.

2017

A new logo to support the strategy

Saipol has a new more modern, more “vegetal” logo, which reflects Saipol’s ambition to move forward, innovate, and lead the entire sector in its transformation. The letter “o” in Saipol’s name shows a leaf, which illustrates Saipol’s core business in plant processing, a seed, which illustrates the crushing of oilseeds, and a green flame, which represents Saipol’s role in renewable energy from plants.

2017

Start of sunflower lecithin production

2018

Launch of Feedmarket

In February 2018, Saipol launched the Feedmarket e-commerce solution for the sale of protein-rich cakes to feed manufacturers and farmers.

Learn more about Feedmarket

2018

Launch of Oleo100 energy

At the end of 2018, Oleo100, a new energy from French rapeseed produced by Saipol, and intended for transport and community fleets, was officially launched.

On 26 December 2018, after initial tests at our customers’ sites, the first tanker carrying Oleo100 was loaded from the Saipol plant in Grand-Couronne and headed for the Rhône.

Learn more about Oleo100

2019

Refocusing by Saipol on specialities

In November 2019, Saipol announces its refocusing on speciality products and the resizing of its industrial park.

2020

Launch of OleoZE

In the spring of 2020, Saipol rolled out its OleoZE offer for the purchase of oilseeds from sustainable farming practices from farmers and collecting organisations.

The seeds collected via OleoZE ensure, via a calculator, that the real values of GHG reduction linked to farms are taken into account. Saipol processes the seeds into biodiesel with high GHG reduction and remunerates the farmers via a GHG bonus for their sustainable agricultural practices and their role in storing carbon in the soil.

OleoZE is available at www.oleoze.fr and from certified partner collecting organisations.

The seeds collected via OleoZE ensure, via a calculator, that the real values of GHG reduction linked to farms are taken into account. Saipol processes the seeds into biodiesel with high GHG reduction and remunerates the farmers via a GHG bonus for their sustainable agricultural practices and their role in storing carbon in the soil.

OleoZE is available at www.oleoze.fr and from certified partner collecting organisations.

2020

100 customers for Oleo100

On 23 June 2020, Saipol teams signed the 100th Oleo100 customer. As of June, 100,000 kilometres are already being driven every day fueled with energy from French rapeseed, which reduces GHG emissions by 60%. Thanks to these first 100 customers, 9,098,000 kg of CO2* (GHG equivalent) were not emitted into the atmosphere thanks to choosing our sustainable and immediately substitutable alternative to fossil diesel.

2020

Reindustrialisation of the Saipol site in Dieppe

The Avril Group announces the reindustrialisation of the Saipol site in Dieppe to produce, in partnership with Royal DSM, vegetable proteins from rapeseed.

For more information, visit

Consolidation of the strategy for Saipol

2020-2024

2021

1 year for Oleoze with 80 000 tonnes of substainable seeds harvested

Launched in February 2020 in “beta” version, Oleoze, the low-GHG seeds sales solution from Saipol (Avril subsidiary), has convinced many farmers and collecting organizations since 80 000 tonnes of substainable seeds have been collected from the first year activation thanks, in particular, to additional remuneration for seeds in the form of GHG bonuses.

2021

Europorte and Saipol united to decarbonize railway ailways with Oleo100

Europorte and Saipol have signed a trial agreement for the use of Oleo100 in commercial service. This is a first in France for locomotives pulling freight trains.

2023

Oleo100 has more than 1000 customers!

In February 2023, Oleo100 reached the notable milestone of 1000 users throughout France, only 4 years after its launch. A symbolic step for the Oleo100 brand which is entering a new turning point in its deployment.

2023

Valorization of seeds from soil regeneration agriculture

Saipol continues its developments towards the valorization of seeds from soil regeneration agriculture and participates in programs with upstream agricultural partners.